Rubber compression stress relaxation Tester agencies|Stress relaxation test system : agency ISO 48— Rubber, vulcanized or thermoplastic -- Determination of . SYBO 4.4 15,987,575 votes. Subway Surfers is a classic endless runner game. You play as Jake, who surfs the subways and tries to escape from the grumpy Inspector and his dog. .

{plog:ftitle_list}

Crie a sua conta no Leitura. Formulário de Cadastro * Usuári.

Test methods for compression stress relaxation

Our experts measure the stress relaxation properties of rubber and plastic polymer materials, evaluating aging properties and liquid resistance.Determination of stress-strain characteristics in compression. High .Temperature and frequency of the stress are additional variables that are .

Our plastic and rubber testing laboratories are uniquely equipped to conduct low .

ISO 48— Rubber, vulcanized or thermoplastic -- Determination of .

Tear resistance testing measures the force required to tear a polymerr test piece, .The frictional properties of rubber and plastics are critical to the real-world .Standard Test Method for Vulcanized Rubber and Thermoplastic Elastomer - Determination of Force Decay (Stress Relaxation) in Compression. Summary. This test method assesses the .

Compression stress relaxation (CSR) testing: considerations in an era Of ISO 17025 proficiency testing. Paul Tuckner, Grace Technology & Development. In looking at elastomer testing in general and CSR testing in .

ISO 6914 describes the testing of stress relaxation in tension. This can be done by two methods, either on continuously stretched samples or intermittent stretched samples. The test . Measuring stress relaxation of rubbers in compression is a key test that is used to estimate the long term sealing behavior and performance life of seals, o-rings and gaskets.

Here’s a brief overview of compression set, stress relaxation and creep, and how each relates to commercially available gasketing materials. What is compression set? – Compression set of rubber materials expresses .Stress Relaxation test system – ISO3384. The Stress relaxation test system performs tests on rubber materials according to NEN ISO 3384-1 and 2 or ISO 6914 standard. A widely applicable Endurance Test system for the continuous .Kiwa has professional test facilities to test the stress relaxation of rubber and TPE as a function of time at various temperatures. The relaxation tests are carried out according to ISO 6914 or . ASTM D6147-97 (2020) Standard Test Method for Vulcanized Rubber and Thermoplastic Elastomer—Determination of Force Decay (Stress Relaxation) in .

Compression Stress Relaxation involves measuring the Sealing Force a Test Specimen projects onto mating surfaces when compressed a defined amounts and exposed to elevated . Experience with compression stress relaxation measurement was not particularly widespread when the ISO standard was first formulated, a variety of apparatus was in use and reproducibility was not good. . Test methods for rubber ‘O’ rings. Google Scholar ASTM F36, 2015. Compressibility and recovery of gasket material. Google Scholar ASTM .

Stress relaxation test system

were detached for compression set test and stress relaxation test at 25% strain levels individually at room temperature for every selected time. The test procedure follows the GB/T 7759.1-2015 and GB/T 1685-2008 standards. The data obtained in this study may be used to investigate the effect of different operating conditions, acids,under compression, but the tensile test has been considered in this work. There are also different standards for implementation of this experiment; samples of rubber have been taken according to the . Reducing of stresses in rubber – stress relaxation is a joint expression of the elastic and viscous properties of the material. We apply the .but decreases with time; this behaviour is called “stress relaxation”. Conversely, when rubber is subjected to a constant stress, an increase in the deformation takes place with time; this behaviour is called “creep”. Tests in compression are normally made under continuous stress conditions (i.e. the test piece remains Intermittent compression stress relaxation (CSR) testing was used to examine the degradation of a large scale chloroprene rubber (CR) O-ring, rather than a reduced scale copy, as well as predict its life-time. An intermittent CSR jig was designed by considering the O-ring’s environment during use. The testing allowed the observation of the effects of friction, .

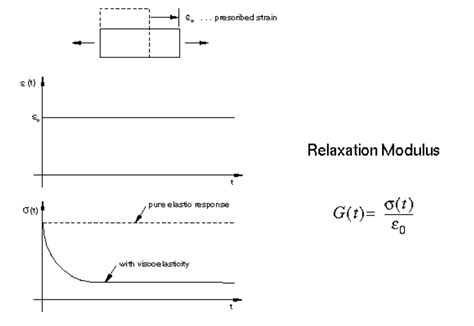

Figure 2. Stress Strain curve of the instantaneous elastic response of the rubber defined by means of a Neo-Hooke strain energy potential. 2. Figure 3 shows the time-dependent behaviour of the rubber evaluated though a stress relaxation test at 5% strain. The material will be modelled with a linear

The findings can give the localized phenomena of vulcanized rubber during a stress relaxation test, which can be used as a guideline for the design, usage, and improvement of rubber and viscoelastic polymeric components. . In each level of compression, the stress relaxation tests were repeated 3 times, and their average was used for the .The Compressive Stress Relaxation Test (DIN) ISO 3384-1 describes two methods for determining stress relaxation under pressure. In addition, the American SAE J 2979 also defines tests for compressive stress relaxation. An elastomer specimen is compressed with a constant load and the force it exerts against this external influence is measured.Compression stress relaxation (CSR) testing is a typical method for measuring the sealing force of an O-ring and widely used for life-time prediction. CSR testing was stan-dardized as an international standard, ISO 3384 in 1979. R. P. Brown and F. N. B. Bennett reported CSR test methods and evaluated its basic characteristics by the type of testbut decreases with time; this behaviour is called “stress relaxation”. Conversely, when rubber is subjected to a constant stress, an increase in the deformation takes place with time; this behaviour is called “creep”. Tests in compression are normally made under continuous stress conditions (i.e. the test piece remains

Stress Relaxation Testing of Raw Rubber, Unvulcanized Rubber Compounds, and Thermoplastic Elastomers1 This standard is issued under the fixed designation D6048; the number immediately following the designation indicates the year of . compression, the ratio of the diameter of the specimen to its height. 3.1.17 compression modulus, n .a MTS.831 Elastomer tester equipped with pneumatic grips. The compression velocity was 5 mm/min. CONTINUOUS COMPRESSION STRESS RELAXATION (CCSR) MEASUREMENTS - Apparatus - The new con-tinuous compression stress relaxation (CCSR) apparatus is specially constructed for continuously monitoring the stress relaxation of elastomer components in .

of rubber. From the beginning stress relaxation tests were predominantly used in scientific projects at . project was financed by the Swedish Energy Agency and participating . which enables stress relaxation test in compression with forces up to 45 kN (45 000 N). The compression is made in an externalOur rubber and plastic testing experts have years of experience conducting accelerated aging testing to industry standards and custom specifications. Common Standards for Stress Relaxation Testing. ASTM D6147—Standard Test Method for Vulcanized Rubber and Thermoplastic Elastomer—Determination of Force Decay (Stress Relaxation) in Compressionof rubber. From the beginning stress relaxation tests were predominantly used in scientific projects at . project was financed by the Swedish Energy Agency and participating . which enables stress relaxation test in compression with forces up to 45 kN (45 000 N). The compression is made in an external

Rubber, vulcanized or thermoplastic — Determination of stress relaxation in compression — Part 1: Testing at constant temperature . Caoutchouc vulcanisé ou thermoplastique — Détermination de la relaxation de contrainte en compression — Partie 1: Essais à température constante . This is a preview of "ISO 3384-1:2011".

Service lifetime of ethylene propylene diene monomer (EPDM) rubber at room temperature (25 °C) was estimated based on accelerated aging tests. The study followed sealing stress loss on compressed cylinder .

given time during a stress relaxation test. 3.1.5 relaxed stress—the initial stress minus the remaining stress at a given time during a stress relaxation test. 3.1.6 stress relaxation curve—a plot of the remaining or relaxed stress as a function of time. 3.1.6.1 Discussion—A curve to demonstrate that the stress relaxation behavior can be . A universal testing machine was used for the uniaxial compression stress and strain test. The uniaxial compression test adopts the displacement control method, and the loading rate is 2 mm/min. . Revealing effects of chain scission during ageing of EPDM rubber using relaxation and recovery experiment. Polym. Test., 56 (2016), pp. 261-268, 10. .The most important factor in achieving good repeatability and reproducibility when making stress relaxation tests is to keep the compression constant during all measurements. The two cycling test methods specified are designed to carry out the following: — age the test piece by stress relaxation and determine the sealing force at low temperaturescalculation parameters by nite element analysis compared with stress relaxation test data. Then, the ANSYS-PDS (ANSYS-probabilistic design system) module is used to analyze the sensitivity values of all random parameters to surface contact stress . used to simulate the compression of rubber sealing gaskets is shown in Fig. 3. In the .

Kiwa has professional test facilities to test the stress relaxation of rubber and TPE as a function of time at various temperatures. The relaxation tests are carried out according to ISO 6914 or ISO 3384. . This sealing pressure is decreasing in time at constant compression or tension due to stress relaxation of the rubber material. At the . Compression Stress Relaxation (CSR) continues to be an important attribute in the evaluation of materials and seal configurations for their ability to provide sealing force retention under a range of conditions. . Citation: Tuckner, P., "Compression Stress Relaxation Testing - Comparisons, Methods, and Correlations," SAE Technical Paper 2001 .Creep Test The creep test, also known as the stress relaxation test, is a destructive way of evaluating a material’s durability and thermal stability. A creep test is one in which the specimen is heated for an extended period and supplied with a constant tensile force or tensile stress. There is a clear delineation between [.]This study applied compression stress relaxation testing and residual seal force testing for time-dependent experimental data collection. These experiments were followed by modeling fit calculations based on the Maxwell-Wiechert theory modified with the Kohlrausch-Williams-Watts stretched exponential function, resulting in a nonlinear, time .

Considering the different stress relaxation mechanisms reported in the literature (Abu-Abdeen, 2010, Mohammad and Mohammadian-Gezaz, 2011, Maria et al., 2014), the stress relaxation observed in the first few seconds of the test (pair A 1 and τ 1) occurred mainly due to the rupture of highly stressed rubber chains (rubber matrix contribution .ISO 3384-2 was prepared by Technical Committee ISO/TC 45, Rubber and rubber products, Subcommittee SC 2, Testing and analysis. ISO 3384 consists of the following parts, under the general title Rubber, vulcanized or thermoplastic — Determination of stress relaxation in compression: — Part 1: Testing at constant temperature

WEBJogos de Halloween - Jogue Online no Papa Jogos. Aliens. Bruxas. Monstros. Terror. Zumbis. Todas Categorias. Futebol. Mario. Meninas. Carros. Motos. Esportes. Infantis. .

Rubber compression stress relaxation Tester agencies|Stress relaxation test system